Custom

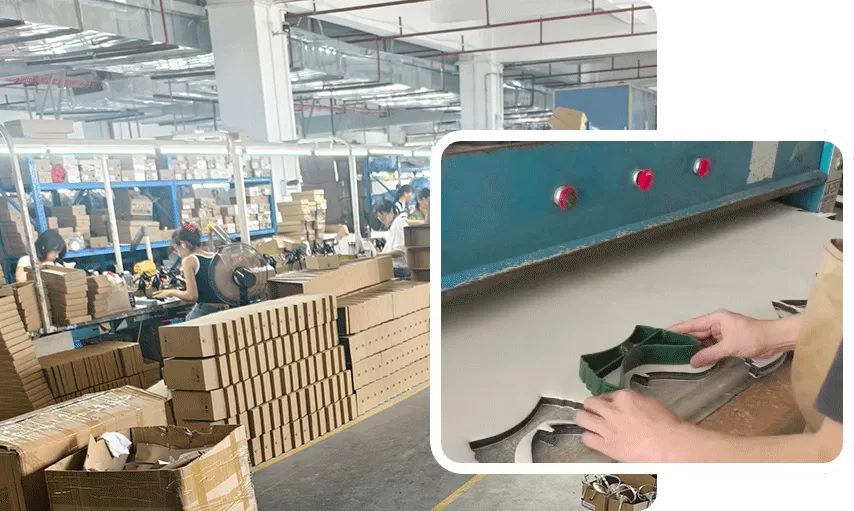

High Heel Manufacturers

We not only offer original and fashionable high heels, but also ensure that every pair undergoes precise high heel production, with meticulous stitching and polishing, striving for perfection in every detail.detail.

Explore our products and services, backed by 20+ years of craftsmanship and quality in making high heels to perfection.

Feel free to contact us anytime. We specialize in heel crafting and customizing products to meet your specific needs. Share your design sketches or materials, and we'll transform your concepts into marketable products.

Material & Leather Prep

The quality of high heels largely depends on the leather. High-end shoes use genuine leather (e.g., cowhide, sheepskin), which is softened to enhance flexibility and reduce discomfort from stiffness after wear.

Cutting & Design Alignment

Automated cutting based on patterns, with manual adjustments for complex areas. Size deviation ≤1mm. After cutting, each leather piece aligns with the shoe design, ensuring correct arrangement, stitching direction, and texture.

Hidden Stitching

High-quality nylon or polyester thread with double-needle hidden stitching (3-4 stitches/cm). Embellishments (e.g., rhinestones/buttons) are hand-fixed, and binding is 9-10mm wide, smooth and wrinkle-free.

Toe Shaping

The toe is shaped using a steam molding machine at a temperature controlled between 80-100℃ to ensure that the toe shape is stable and does not deform. The shoe shape fits the standard shoe last without any wrinkles or discoloration.

Upper Stitching & Bonding

The upper and side are meticulously stitched with even, tight seams, ensuring no skipped or broken stitches and a seam strength ≥ 8N. The PU coating is also rigorously checked for integrity, ensuring flawless detail.

Heel Refining

In making high heel shoes, the heel surface is polished, spray-painted or fabric-wrapped, and a rubber anti-slip pad is applied and pressed for 10 minutes, ensuring vertical deviation within 1° to meet precision standards.

Sole Treatment

Glue is evenly applied to the upper, left to set for 5-8 minutes, then pressed at 5-8MPa for 20 seconds. This ensures no misalignment, no visible glue marks, and a peel strength ≥ 3N/mm, meeting high standards.

Heel Assembly

As high heels manufacturers, we fix the heel with screws, reinforce it with glue, and allow it to cure for 24 hours. This process ensures the heel shifts ≤ 0.5mm and remains free of deformation under 50kg of weight, guaranteeing stability and durability.

Lining & Comfort

The shoe lining is usually made of genuine leather (pigskin/sheepskin), which not only improves the comfort of the shoe, but also reduces the irritation to the feet from wearing it for a long time.

Edge Trim & Sanding

After trimming edges and glue marks, the seams are finely sanded for smoothness. Then, an antibacterial spray is applied inside to keep it fresh, and memory foam insoles are added for added comfort, ensuring perfect detail.

Quality Check & Adjustments

Each pair undergoes strict quality checks for scratches, color differences, and intact embellishments. Then, performance tests are conducted, ensuring no cracks after 200 flex cycles and meeting slip-resistance standards. Finally, a fitting test ensures good comfort and no rubbing.

Packaging & Shipping

Each pair is placed in a dust bag, with a branded box, certificate, and care instructions. They are then packed in batches with cushioning material for safe transport.